CNC Multi-Torch

& Plasma Cutting System

- Machine Flame Cutting

- Usage of Oxygen and Combustible Gas by exerting pressure in the mixture

- Heat-focused and narrow band melting at 1500 degree celsius

- Attainment of quick cuts through the process

- Inclusion of distortion due to rapid thermal heating cycle and cool residual stress

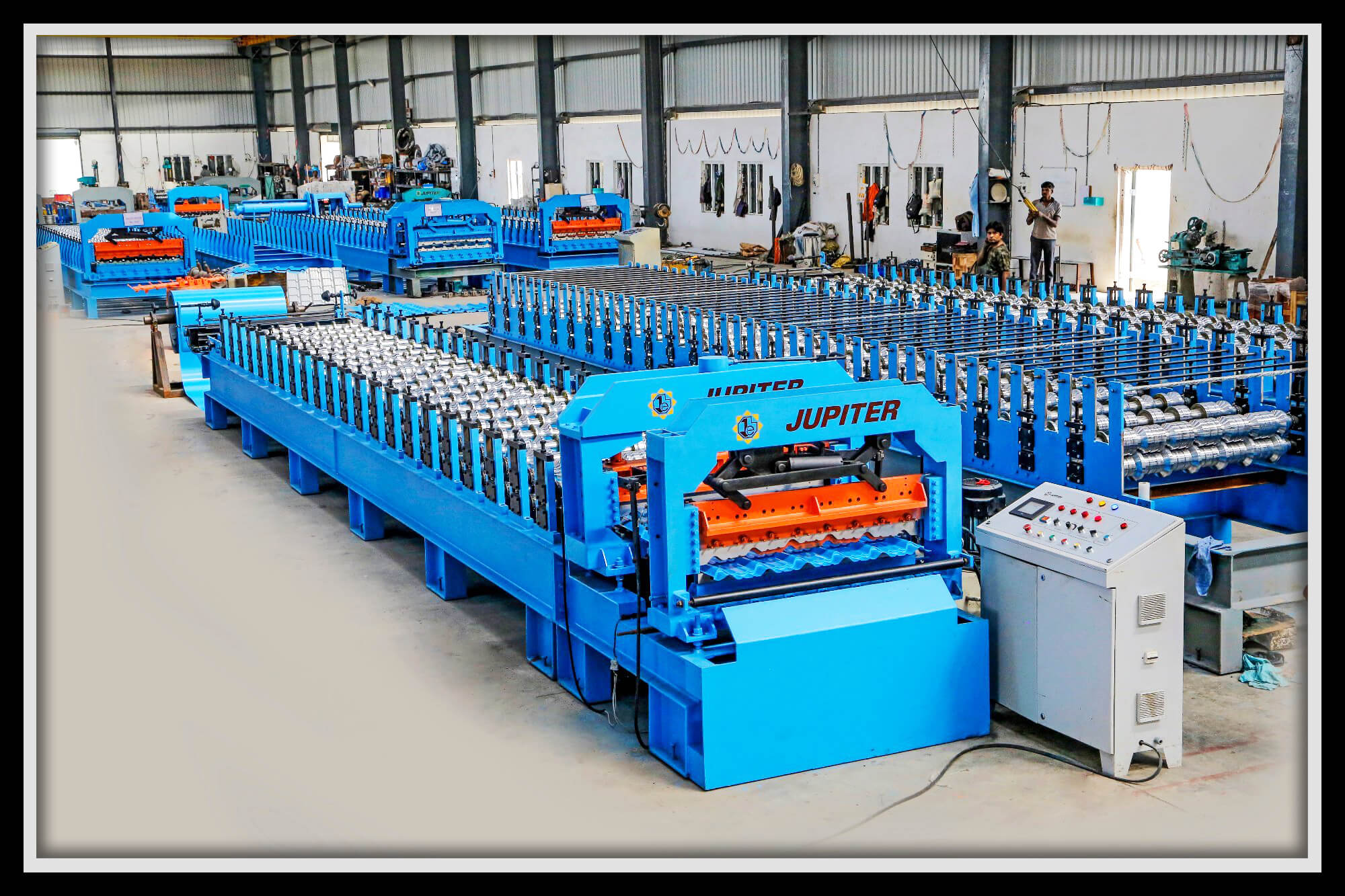

HV Series Roll Forming Machine

- Raw materials used include pre-painted galvanised steel Sheet ASTMA 526/JIS G3302 SGCC or other soft material of the same class

- Coil thickness: 0.35 mm – 0.8 mm for 550 MPa, Effective width: 1225 mm

- Line speed: max. 20 m/min

- Uncoiler Load capacity: 6MT

Quick Integration C & Z punching Machine

- Inclusive of pre-levelling, pre punching and pre cutting device

- Thickness ranges to 1.5 mm-3.5 mm for 345 MPa & U.S.T 550 MPa Z100-Z 350, C100-C350

- Speed capacity is 25m/min

- +2mm corners with pre-programmed feature

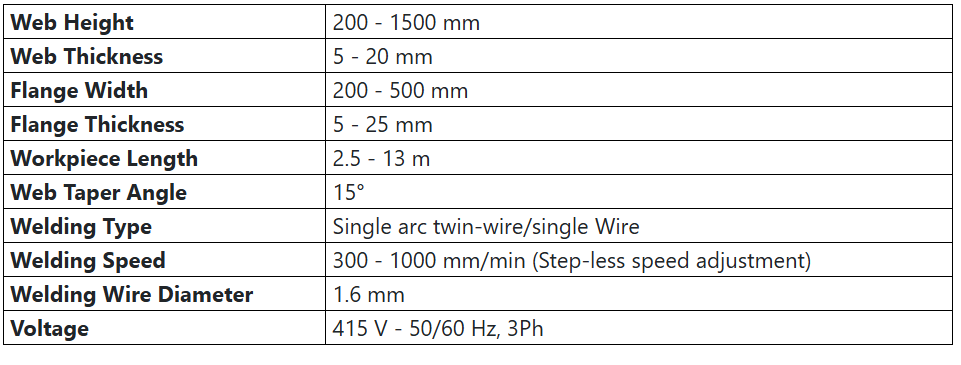

Heavy Duty H-Beam Welding Line

Duty 3 M Press Brake Heavy

Capacity

- 1500 KN

- Max Working length - 3150 mm

- Frame distance is 3000 mm

Capacity

- Availability of Hydraulic Shears for cutting and cropping the length and width sections

- Shearing Knives for cutting smaller plate sections

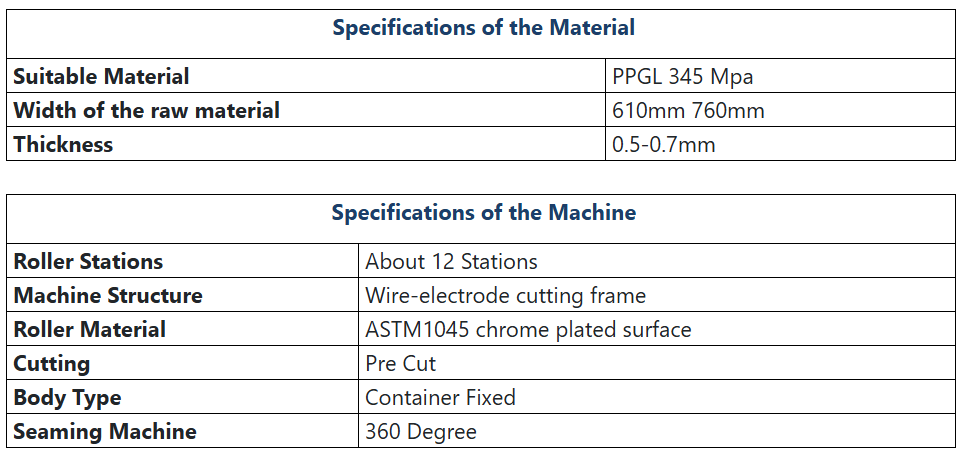

Standing Seam Dual Profile Rool Forming machine