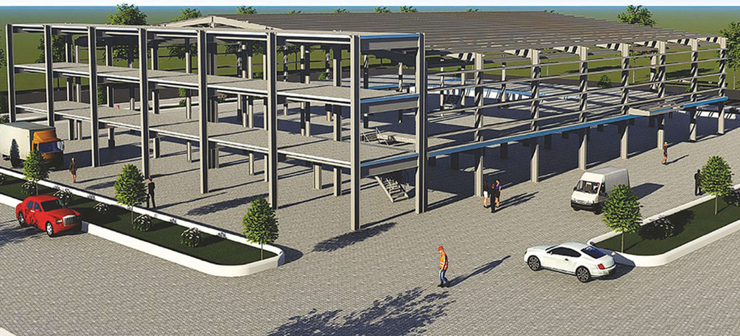

Tunwal E Motors, Sikar

Steelbuild Infra Projects Pvt. Ltd. has successfully completed numerous projects that showcase the company’s expertise in the field of pre-engineered buildings (PEB). One of the remarkable projects completed by the company is the Tunwal E Motors PEB building located in Sikar, Rajasthan, India. This project highlights Steelbuild’s proficiency in providing durable, cost-effective, and high-quality structures that meet the unique needs of businesses across various industries.

Project Overview

The Tunwal E Motors project involved the construction of a state-of-the-art facility in Sikar, Rajasthan, dedicated to the manufacturing and assembly of electric vehicles. As the demand for eco-friendly transportation solutions continues to rise, the establishment of a modern production facility for electric vehicles (EVs) required a building that not only supported the operational requirements but also offered long-term sustainability. Steelbuild Infra Projects was entrusted with designing and constructing a PEB building that could meet the specific demands of an automotive manufacturing environment.

Design and Construction Features

Tailored for Manufacturing

The primary requirement for the Tunwal E Motors building was to provide a spacious, adaptable, and functional space for the assembly and manufacturing of electric vehicles. Steelbuild’s team designed a large open-plan layout, ensuring sufficient space for various production stages, including assembly lines, quality control zones, storage areas, and administrative offices. The building’s flexible design also allowed for future expansion or modifications to accommodate growing production needs or technological upgrades.Structural Strength and Safety

Manufacturing facilities, especially those in the automotive sector, require robust structures capable of supporting heavy machinery, equipment, and inventory. Steelbuild’s use of high-grade steel for the PEB ensured that the Tunwal E Motors building was both structurally sound and able to bear the weight of large machinery, assembly lines, and other essential manufacturing components. The building was designed with safety in mind, including features like fire-resistant cladding, safe access routes, and compliance with industry safety standards.Energy-Efficient Design

Sustainability is at the core of the electric vehicle industry, and Steelbuild ensured that the Tunwal E Motors building was equally energy-efficient. The building features insulated walls and roofs that minimize heat transfer, reducing the need for artificial heating or cooling. The incorporation of natural lighting through strategically placed windows and skylights further reduced reliance on electricity, contributing to the building’s energy efficiency. These eco-friendly elements align with the client’s commitment to sustainability in manufacturing and operations.Fast-Track Construction

One of the standout benefits of using pre-engineered buildings is the speed of construction. For Tunwal E Motors, Steelbuild leveraged its prefabrication process, manufacturing key components off-site, allowing for quick assembly on-site. This significantly reduced the construction timeline, enabling the client to start operations much sooner than with traditional building methods. The timely completion of the project ensured that Tunwal E Motors could begin production and contribute to the rapidly growing electric vehicle market.Cost-Effectiveness and Scalability

The use of pre-engineered building technology not only shortened construction time but also kept costs manageable. Steelbuild’s efficient design and material sourcing process allowed the company to deliver a cost-effective solution without compromising on quality. Additionally, the PEB design provided the scalability required for future expansion. As Tunwal E Motors grows and demands increase, the facility can easily be expanded or modified to meet new requirements.

Client Benefits

The Tunwal E Motors PEB building offers numerous advantages to the client:

- Adaptable and Spacious: The building’s open layout allows for flexibility in organizing production lines and accommodating new technologies or equipment.

- Strong and Safe: The robust structure ensures that the building can support heavy machinery and high operational demands, while meeting safety standards.

- Sustainable and Energy-Efficient: The energy-efficient design reduces operational costs and aligns with the client’s focus on sustainability.

- Timely Completion: The fast construction timeline allowed the client to launch operations promptly and meet market demands.

- Scalability: The building’s modular design allows for easy expansion as production demands grow.

Final Thoughts

The Tunwal E Motors PEB building in Sikar, Rajasthan, is a perfect example of Steelbuild Infra Projects’ ability to deliver high-quality, cost-effective, and sustainable pre-engineered buildings for diverse industries. This project not only meets the immediate operational needs of the electric vehicle manufacturer but also positions the facility for future growth. By choosing Steelbuild, Tunwal E Motors was able to establish a modern, efficient, and flexible manufacturing facility that supports their long-term business goals and contributes to the growth of the electric vehicle industry in India.

Project Information

Project Name: Tunwal E Motors

Area: 2155.32 Sq. Mtr.

Tonnage: 86 MT

Project Date: 25 June, 2024

Avenue End Date: 08 July, 2024

Location: Sikar, Rajasthan, India