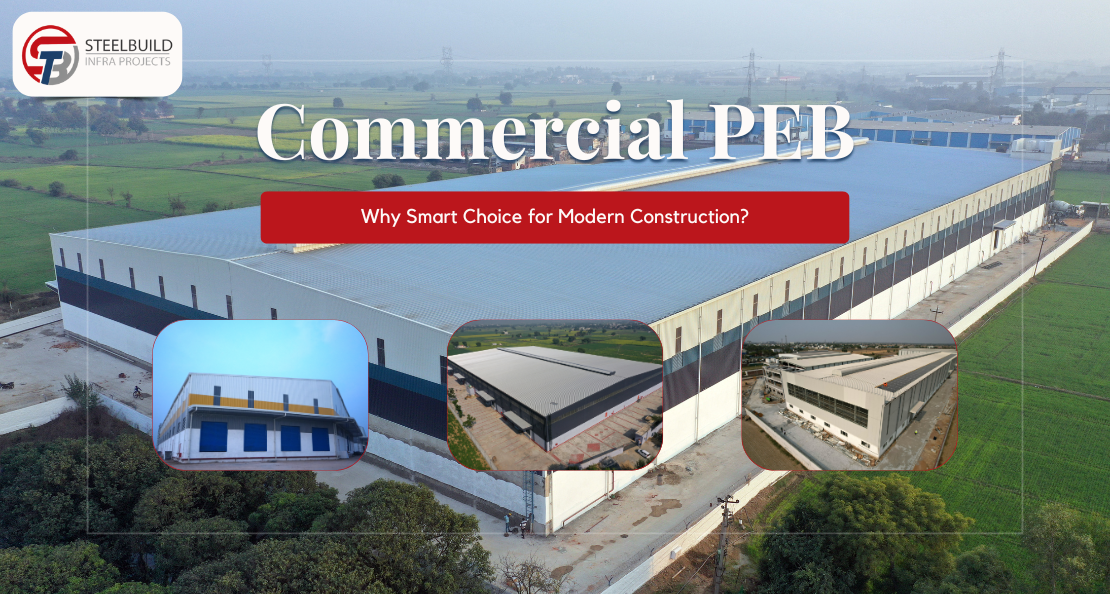

Commercial PEBs are a Smart Choice for Modern Construction?

Introduction

The commercial construction industry is evolving rapidly as cities expand and businesses require more efficient, durable, and cost-effective building solutions. Traditional construction methods, while effective, often face delays, cost overruns, and inflexible designs. This has led to the rise of pre-engineered commercial buildings (PEBs) as a smarter alternative.

Pre-engineered buildings offer speed, strength, adaptability, and sustainability, making them the perfect choice for various commercial applications. From warehouses and industrial sheds to retail centers and office spaces, PEBs have transformed how we approach construction.

In this comprehensive guide, we will explore the numerous advantages of pre-engineered commercial buildings and why they are the future of modern construction.

The Growing Demand for Pre-Engineered Commercial Buildings

Businesses today need structures that can evolve with them. The ability to expand, modify, or repurpose buildings is crucial for long-term success. Pre-engineered buildings address this need by offering unparalleled customization and scalability.

These buildings are designed with precision in factories, minimizing on-site disruptions and ensuring faster completion. Their durability and adaptability make them the preferred choice for commercial, industrial, and institutional projects.

The rising popularity of PEBs can be attributed to several key benefits, which we will explore in detail below.

Faster Construction Timelines

One of the biggest advantages of pre-engineered commercial buildings is their speed of construction. Unlike traditional construction, which follows a sequential process, PEBs allow for simultaneous off-site fabrication and on-site preparation. This significantly cuts down the overall construction timeline.

Why is PEB construction faster?

- Factory-Based Manufacturing: PEB components are manufactured in a controlled environment, reducing delays caused by weather, labor shortages, or material unavailability.

- Pre-Fabricated Components: Structural elements such as beams, columns, and panels arrive at the site ready for assembly, eliminating on-site fabrication time.

- Minimal On-Site Work: Since most of the work is done off-site, only assembly and installation take place at the construction site, drastically reducing labor and project duration.

For example, a traditional warehouse may take a year to construct, while a PEB warehouse can be completed in just a few months. In fast-moving economies like India, where businesses need to start operations quickly, this advantage is crucial.

Enhanced Durability and Strength

Pre-engineered commercial buildings are designed to withstand extreme environmental conditions and long-term usage. They are constructed using high-quality materials such as galvanized steel, aluminum, and advanced coatings, ensuring superior durability.

Key Strength Features:

- Weather Resistance: PEBs can withstand heavy rains, strong winds, seismic activity, and extreme temperatures.

- Fire Resistance: Many PEB materials are fire-resistant, adding an extra layer of safety.

- Corrosion and Rust Protection: Special coatings and high-grade steel make these buildings more resilient in humid or coastal areas.

In a country like India, where climate conditions vary from coastal humidity to extreme heat, these durable structures provide a long-lasting solution with minimal maintenance.

Cost-Effective Construction for Commercial Projects

Pre-engineered buildings offer a significant cost advantage over traditional methods.

How do PEBs reduce costs?

- Efficient Material Use: Unlike traditional buildings, where material wastage is common, PEBs use materials efficiently, leading to cost savings.

- Lower Labor Costs: Since much of the work is automated in factories, the need for on-site labor is reduced.

- Faster Project Completion: Time is money in construction, and shorter timelines mean lower overhead costs.

- Low Maintenance Costs: Due to their durability, these buildings require fewer repairs over time.

PEBs are like building blocks—they can be expanded in the future, eliminating the need for costly renovations or new constructions as businesses grow.

In India, where budget constraints often affect commercial projects, the affordability of PEBs makes them a game-changer.

Customization and Flexibility

One of the standout features of pre-engineered commercial buildings is their flexibility in design and customization. Whether you need an expansive warehouse, a high-tech manufacturing facility, or a modern office space, PEBs can be tailored to suit specific business needs.

What makes PEBs highly customizable?

- Modular Construction: Components can be added or removed without disrupting operations.

- Diverse Applications: Suitable for industries such as retail, logistics, healthcare, education, and hospitality.

- Innovative Designs: Available in various architectural styles, colors, and finishes.

For example, Steelbuild Infra, a leading PEB manufacturer in India, has successfully delivered pre-engineered solutions for schools, hospitals, warehouses, and even auditoriums.

Sustainability: Building a Greener Future

As the world moves toward sustainable construction practices, pre-engineered buildings stand out as an environmentally friendly option.

How do PEBs support sustainability?

- Reduced Waste: Since components are factory-made, material wastage is significantly lower than traditional construction.

- Energy Efficiency: PEBs are designed with insulation options that reduce heating and cooling energy consumption.

- Recyclable Materials: Steel and aluminum used in PEBs are 100% recyclable, reducing environmental impact.

- Lower Carbon Footprint: The efficient construction process results in fewer emissions and less disruption to surrounding areas.

In India, where environmental concerns are growing, PEBs offer a sustainable solution for businesses looking to reduce their carbon footprint.

Real-World Applications of Pre-Engineered Commercial Buildings

Pre-engineered buildings are widely used in various industries. Let’s look at some of their most common applications:

1. Warehouses and Logistics Centers

PEBs provide large, open spaces without the need for columns, making them ideal for warehouses and storage facilities.

2. Industrial and Manufacturing Plants

Factories benefit from PEBs due to their ability to withstand heavy machinery loads and offer customizable layouts.

3. Commercial Office Spaces

Companies are opting for pre-engineered office buildings due to their modern designs and cost savings.

4. Retail Showrooms and Shopping Centers

PEBs allow for quick construction and attractive designs, perfect for retail businesses.

5. Educational Institutions and Healthcare Facilities

Schools and hospitals are increasingly using PEBs due to their cost-effectiveness and faster construction times.

Challenges and Considerations

While PEBs offer numerous benefits, there are some challenges to consider:

- Initial Design Requirements: Requires careful planning to ensure proper customization.

- Limited On-Site Modifications: Once components are manufactured, on-site changes can be challenging.

- Transportation Logistics: Large prefabricated components require specialized transport, which can increase costs.

However, these challenges can be mitigated by working with experienced manufacturers and planning efficiently.

Conclusion: The Future of Commercial Construction

Pre-engineered commercial buildings have revolutionized the construction industry, offering an affordable, durable, and sustainable alternative to traditional construction.

As businesses continue to demand fast, flexible, and cost-effective solutions, PEBs will only gain more traction. From reducing construction timelines to enhancing durability and supporting green initiatives, these buildings are shaping the future of modern construction.

If you’re considering a commercial project, now is the time to explore pre-engineered solutions. Leading manufacturers like Steelbuild Infra provide tailored PEB solutions that can help businesses maximize efficiency and long-term savings.

Make the right choice today and embrace the future of commercial construction with pre-engineered buildings!

Our Similar Posts:

Click Here 👉 Pre Engineered Buildings Introductions and Features

Click Here 👉 Pre Engineered Buildings Introductions and Features Steelbuild Roofing Sheets

Click Here 👉 Steelbuild Cladding Sheets: Transforming Modern Architecture with Strength and Style

Click Here 👉 Standing Seam Roofing Sheets: Revolutionizing Modern Architecture with Durability & Style

Click Here 👉 Steelbuild Deck Sheets: The Ultimate Solution for Durable and Efficient Flooring Systems

Click Here 👉 Enhancing Building Performance: A Comprehensive Guide to Sheeting Accessories by Steelbuild

Click Here 👉 Role of Insulation in Modern Infrastructure: A Comprehensive Guide

Click Here 👉 Enhancing Pre-Engineered Building Construction: A Comprehensive Guide to Accessories

Click Here 👉 Industrial Coating: Building the Dream Project with Care

Click Here 👉 Unleashing Excellence in Construction: Steelbuild’s Project Management Consultancy

Click Here 👉 Revolutionizing Construction with Steelbuild Infra’s Advanced Plant Facility

View Post in LinkedIn Click Here